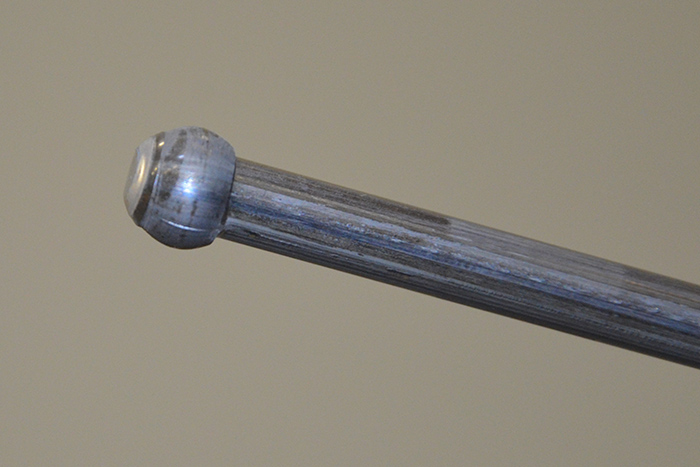

Button head with a small crack

Button head with a small crack

Button-headed prestressing wires are frequently used in the manufacture of railway sleepers, poles and towers and are produced in series on automatic button heading machines. Replacing faulty prefabricated button-head tendons in subsequent processes would cause downtimes, rework or increased material consumption.

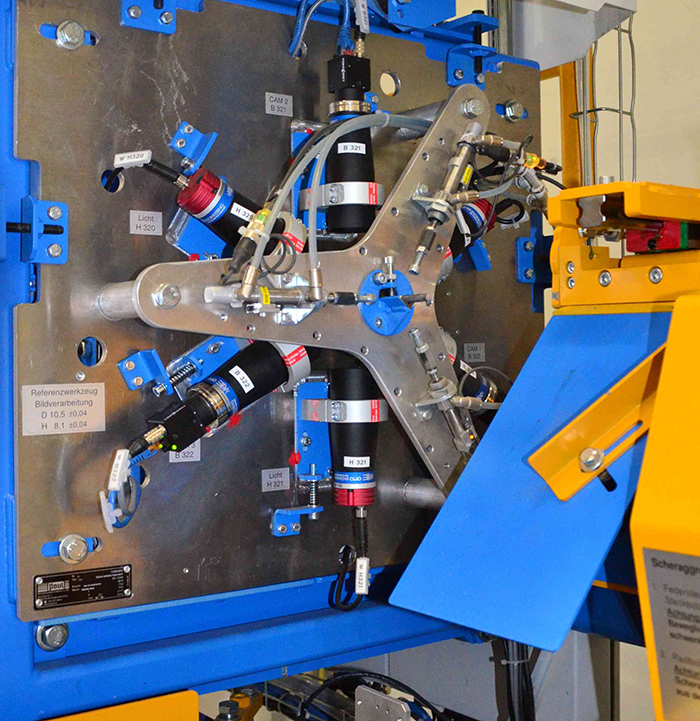

A camera system with modern image processing technology detects faulty button heads at an early stage, thus saving time and money.

Each button head is inspected within approx. 10 seconds including positioning and fastening of the prestressing steel between three cameras, each of them taking two pictures with different lighting. To ensure that the button heads are inspected from all sides, the cameras are arranged at an angle of 120° to one another.

Whilst the button-headed wire is automatically transferred to the subsequent processes, the evaluation of the inspection is displayed on the monitor. The reliability of the image processing system is approx. 99.5%.

Please let us know your requirements!